So, you’re drawn to the blue-white arc, the hiss of argon, and the satisfaction of laying a perfect, "stack-of-dimes" bead. You’re considering a career in TIG welding, a path that demands precision, artistry, and immense skill. But beyond the craft, you have a critical question: *Is it a financially rewarding career?* You want to know about the TIG welding salary—what you can realistically expect to earn and how high you can climb.

You've come to the right place. This guide is your blueprint. We will move beyond simple salary numbers and delve into the *why* behind them. We’ll explore the factors that can transform a TIG welder's paycheck from standard to stellar, examine the robust job outlook for this essential trade, and provide a clear, step-by-step roadmap to get you started. The demand for welders who have mastered the intricate art of Gas Tungsten Arc Welding (GTAW), or TIG, is not just steady; it’s intensifying in high-tech, high-stakes industries. While the national average salary for welders provides a solid baseline, specialized TIG welders often command earnings that are 20%, 50%, or even 100% higher.

I once interviewed a lead welding engineer for a major aerospace contractor. He told me, "We don't just hire welders; we invest in artists who work with metal. A single flawed weld on a multi-million dollar component isn't just a mistake; it's a catastrophic failure. We pay a premium for perfection, and our TIG welders deliver that." That sentiment perfectly encapsulates the value and earning potential of a master TIG welder. You are not just joining metal; you are ensuring safety, performance, and innovation in the world's most critical industries.

This comprehensive guide will illuminate every facet of a TIG welding career, empowering you with the knowledge to forge your own prosperous future.

### Table of Contents

- [What Does a TIG Welder Do?](#what-does-a-tig-welder-do)

- [Average TIG Welding Salary: A Deep Dive](#average-tig-welding-salary-a-deep-dive)

- [Key Factors That Influence Your TIG Welding Salary](#key-factors-that-influence-your-tig-welding-salary)

- [Job Outlook and Career Growth for TIG Welders](#job-outlook-and-career-growth-for-tig-welders)

- [How to Become a TIG Welder: Your Step-by-Step Guide](#how-to-become-a-tig-welder-your-step-by-step-guide)

- [Conclusion: Is a TIG Welding Career Worth It?](#conclusion-is-a-tig-welding-career-worth-it)

What Does a TIG Welder Do? The Art and Science of Precision Joining

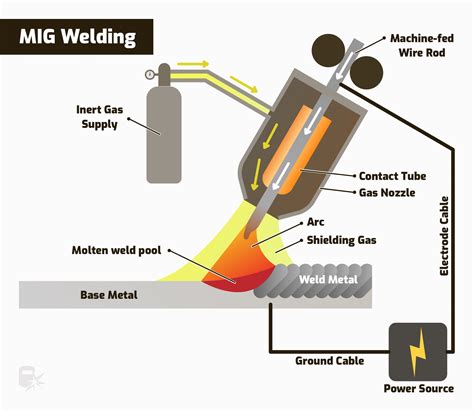

To understand the salary potential of a TIG welder, one must first appreciate the complexity and criticality of the role. TIG welding, or Gas Tungsten Arc Welding (GTAW), is widely regarded as the most challenging and precise of all common welding processes. Unlike MIG (Gas Metal Arc Welding) which uses a continuously fed wire electrode, TIG welding requires exceptional dexterity and control. The welder uses one hand to manipulate a torch that houses a non-consumable tungsten electrode to create the arc, and the other hand to manually feed a separate filler rod into the weld puddle. This two-handed process is controlled by a foot pedal or thumb control on the torch, which regulates the amperage—much like driving a manual car versus an automatic.

This meticulous process produces exceptionally clean, strong, and aesthetically pleasing welds. It's the go-to method for welding thin materials and for applications where weld quality is absolutely paramount. It can be used on a wider range of metals than other processes, including stainless steel, aluminum, magnesium, copper, titanium, and exotic alloys like Inconel.

Core Responsibilities and Daily Tasks:

A TIG welder's job is far more than just melting metal together. It's a technical role that involves planning, preparation, execution, and inspection.

- Blueprint and Specification Analysis: The day almost always begins with reading and interpreting complex blueprints, schematics, and welding procedure specifications (WPS). This tells the welder everything they need to know: the type of material, the thickness, the joint design, the filler metal to use, and the required quality standards.

- Material Preparation: This is a critical, non-negotiable step. TIG welding demands pristine surfaces. The welder will spend significant time cleaning the base metals, removing all oxides, oils, and contaminants using grinders, wire brushes, and chemical solvents. They will also precisely cut, grind, and bevel the edges of the metal to create the perfect joint for welding.

- Machine and Equipment Setup: The welder must set up their TIG welding machine with precision. This includes selecting the correct tungsten electrode (e.g., pure, thoriated, lanthanated), grinding it to a perfect point, choosing the right gas cup size, setting the correct amperage and voltage, and ensuring a proper flow of shielding gas (usually argon or an argon/helium mix).

- The Welding Process (The Craft): This is the core skill. The welder establishes the arc, creates a molten weld puddle, and carefully feeds the filler rod to create a seamless joint. This requires unwavering focus, a steady hand, and an intimate understanding of how the metal behaves under intense heat.

- Quality Control and Inspection: After welding, the job isn't over. The welder must inspect their work for defects like cracks, porosity, or lack of fusion. This can involve visual inspection, using measuring tools like calipers and fillet gauges, and sometimes preparing the weld for more advanced non-destructive testing (NDT) like X-rays or ultrasonic tests.

- Maintenance and Safety: Welders are responsible for maintaining their equipment and adhering to strict safety protocols. This includes wearing appropriate Personal Protective Equipment (PPE) like a welding helmet, gloves, and fire-resistant clothing, and ensuring proper ventilation to avoid inhaling harmful fumes.

### A Day in the Life of an Aerospace TIG Welder

To make this tangible, let's imagine a day for "Alex," a certified aerospace TIG welder working on aircraft components.

- 7:00 AM: Alex arrives, clocks in, and attends a brief team meeting to discuss the day's production targets and any safety updates.

- 7:30 AM: Alex picks up the work order and blueprints for their first job: welding a series of titanium brackets for a jet engine assembly.

- 8:00 AM: Alex spends the next hour in the prep area. They meticulously clean each titanium piece in a controlled environment, ensuring no contaminants are present. They check the fit-up of the parts, making sure the joints are perfect.

- 9:00 AM: Back at their welding booth, Alex configures their machine specifically for titanium. They install a freshly sharpened 2% lanthanated tungsten electrode, set the amperage on their foot pedal, and set the argon gas flow to create the perfect inert shield.

- 9:30 AM - 12:00 PM: The welding begins. With intense focus, Alex uses the foot pedal to control the heat while delicately feeding a thin titanium filler rod into the joint. Each weld is precise, clean, and identical to the one before it, as per the exacting aerospace specifications.

- 12:00 PM - 12:30 PM: Lunch break.

- 12:30 PM - 3:30 PM: Alex continues the welding process, completing the batch of brackets. After each piece cools, they perform a visual inspection under magnification, looking for any minute flaw.

- 3:30 PM: The completed brackets are carefully labeled and sent to the Quality Control department for formal inspection, which may include X-ray testing.

- 3:30 PM - 4:00 PM: Alex cleans their workstation, organizes their tools, and properly stores their welding equipment, preparing for the next day. They log their completed work in the company's tracking system before clocking out.

This example highlights that a TIG welder is a highly skilled technician who blends artistry with scientific principles to create components that simply cannot fail. This level of responsibility is the foundation of their high earning potential.

Average TIG Welding Salary: A Deep Dive into Your Earning Potential

Now, let's get to the numbers. Understanding the salary landscape requires looking at data from multiple authoritative sources. It’s important to note that most data aggregators report on "Welders, Cutters, Solderers, and Brazers" as a broad category. Specialized TIG welders, particularly those in high-demand fields, consistently earn at the upper end of these ranges, and often exceed them.

The U.S. Bureau of Labor Statistics (BLS) is the gold standard for occupational data. As of their latest report in May 2023, the national salary data for all welders is as follows:

- Median Annual Salary: $50,460 ($24.26 per hour)

- Lowest 10% Earned: Less than $37,510

- Highest 10% Earned: More than $72,970

Source: [BLS Occupational Outlook Handbook, Welders, Cutters, Solderers, and Brazers](https://www.bls.gov/ooh/production/welders-cutters-solderers-and-brazers.htm) (Data from May 2023).

While this is a useful starting point, it includes all types of welding and all industries. To get a clearer picture specifically for TIG welding, we turn to real-time salary aggregators that often differentiate by skill.

According to data compiled from sites like Payscale, Salary.com, and Glassdoor (as of late 2023/early 2024), the salary landscape for welders who list TIG (GTAW) as a primary skill is significantly higher.

- Average Base Salary for TIG Welders: Approximately $62,500 per year ($30.05 per hour).

- Typical Salary Range: $45,000 to $85,000 per year.

- Top Earners (Specialized TIG Welders): Can exceed $100,000 to $125,000+ per year.

These figures demonstrate a clear "TIG premium." The specialized skill required for this process directly translates into higher compensation compared to the general welding median.

### Salary by Experience Level

Like any skilled profession, your earnings as a TIG welder will grow substantially with experience. The ability to produce consistent, high-quality welds on challenging materials and in difficult positions is a skill honed over thousands of hours.

Here is a typical salary progression you can expect, based on aggregated data from multiple sources:

| Experience Level | Years of Experience | Typical Annual Salary Range | Key Characteristics |

| :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice | 0-2 years | $38,000 - $52,000 | Has basic TIG training from a vocational school. Works under supervision. Focuses on common materials like mild steel and aluminum in standard positions. |

| Mid-Career / Journeyman | 2-8 years | $55,000 - $78,000 | Proficient in TIG on various materials (stainless steel). Can read blueprints independently. May hold one or more AWS certifications. Works on more complex projects. |

| Senior / Master TIG Welder | 8+ years | $80,000 - $110,000+ | Expert in TIG on exotic alloys (titanium, Inconel). Capable of all-position welding (6G). Holds multiple advanced certifications. Often works in critical industries like aerospace or nuclear. May lead or train other welders. |

| Welding Inspector / Supervisor | 10+ years | $85,000 - $130,000+ | Often a former master welder. Holds a CWI (Certified Welding Inspector) certification. Manages welding projects, ensures quality control, and develops welding procedures. |

*Note: These are national averages. Your specific salary will be heavily influenced by the factors discussed in the next section.*

### Beyond the Paycheck: A Look at Total Compensation

Your annual salary is only one part of the equation. Total compensation includes other valuable benefits that significantly impact your financial well-being. When evaluating a job offer, be sure to consider the full package.

- Overtime Pay: Welding is often project-based, and deadlines are common. Most hourly TIG welders have ample opportunity for overtime work, which is typically paid at 1.5 times the base hourly rate ("time and a half"). For a welder earning $35/hour, each hour of overtime is worth $52.50. Consistent overtime can add tens of thousands of dollars to an annual income.

- Bonuses and Profit Sharing: Many manufacturing and fabrication companies offer annual or quarterly bonuses based on individual performance, team productivity, or overall company profitability.

- Per Diem: This is a crucial factor for traveling welders (e.g., pipe welders, shutdown specialists). A per diem is a daily allowance to cover living expenses (lodging, food) when working away from home. This can range from $75 to $150+ per day, and it's often tax-free, significantly boosting net income.

- Health and Retirement Benefits: Most reputable employers offer comprehensive benefits packages, including medical, dental, and vision insurance. Look for companies with strong retirement plans, such as a 401(k) with a generous employer match.

- Union Benefits: Welders who are members of a union, such as the United Association (UA) of Plumbers and Pipefitters or the Boilermakers, often receive exceptional benefits packages negotiated by the union. This typically includes a defined-benefit pension plan (in addition to an annuity or 401k), excellent healthcare with low premiums, and standardized wage increases.

- Tool and Gear Allowances: Some companies provide an annual allowance for welders to purchase or upgrade their personal tools, welding hoods, and protective gear.

- Paid Time Off (PTO): This includes vacation days, sick leave, and paid holidays, which are a standard part of compensation packages from established employers.

When you combine a strong base salary with overtime, benefits, and potential per diem, the total compensation for a skilled TIG welder can be incredibly competitive, rivaling that of many four-year-degree professions.

Key Factors That Influence Your TIG Welding Salary

Two TIG welders can have the same title but vastly different incomes. A six-figure salary is not just possible; it's common for those who strategically position themselves in the market. Mastering the craft is the first step, but understanding these five key salary drivers is how you maximize your earning potential.

### 1. Certifications and Education

While a four-year university degree is not required, your level of formal training and, most importantly, your certifications, are paramount.

- Vocational School Diploma / Certificate: This is the most common starting point. A 9-18 month program at a technical college provides foundational knowledge and, crucially, thousands of hours of hands-on "booth time." Graduates from reputable programs are far more employable and start at a higher wage than someone with no formal training.

- Associate's Degree in Welding Technology: A two-year degree goes deeper into the science of welding. You'll learn more about metallurgy, non-destructive testing, advanced blueprint reading, and fabrication design. This degree is an excellent stepping stone for future leadership roles like a welding supervisor, inspector, or engineer, and can command a higher starting salary.

- Welding Certifications (The Real Money Maker): This is the single most important factor in this category. Certifications are proof that you have passed a hands-on test and can produce a quality weld according to a specific code or standard. The American Welding Society (AWS) is the primary certifying body in the U.S.

- Entry-Level Certs: An AWS D1.1 (Structural Steel) or D1.2 (Structural Aluminum) certification in a basic position (e.g., 2F - horizontal fillet) shows you have fundamental skills.

- Advanced Certs: This is where salaries skyrocket. Certifications for welding pipe are particularly lucrative. A 6G pipe certification is often considered the gold standard for manual welders. The "6G" position means the pipe is fixed at a 45-degree angle, and the welder must weld around it—welding flat, horizontal, vertical, and overhead all in one continuous pass. A welder with a 6G certification on stainless steel or a more exotic alloy is in extremely high demand.

- Code-Specific Certs: Industries often have their own codes. ASME Section IX certifications are required for welding on pressure vessels and boilers (common in power plants and refineries). API 1104 is the standard for welding on oil and gas pipelines. Holding these certifications opens doors to the highest-paying jobs in the trade.

- Certified Welding Inspector (CWI): For experienced welders, earning an AWS CWI certification is a major career advancement. CWIs are responsible for inspecting welds, ensuring welders are qualified, and maintaining quality control. This is a salaried position that often commands an income of $85,000 to $130,000+.

### 2. Years of Experience and Proven Skill

As shown in the previous section, experience is a direct driver of income. However, it's not just about time served; it's about the *quality* and *variety* of that experience.

- 0-2 Years (Apprentice): Your goal is to be a sponge. Absorb every technique, ask questions, and practice relentlessly. Your value is in your potential and willingness to learn. Focus on achieving perfect beads on common materials.

- 2-8 Years (Journeyman): You are now a reliable, independent welder. Your income grows as you prove you can work efficiently without constant supervision. You should be actively seeking out jobs that involve more challenging materials (like stainless steel) and pursuing your first major certifications (e.g., a 3G/4G plate test or a basic pipe cert).

- 8+ Years (Master Welder): You are the expert. You've encountered and solved countless welding problems. Your reputation for quality is your biggest asset. You are trusted with the most expensive materials and critical components. You can TIG weld titanium, Inconel, or other superalloys "out of position" (i.e., not in a comfortable, flat position). Welders at this level often have a portfolio of work and a network of contacts that bring them high-paying opportunities, including short-term, high-urgency jobs that pay a premium.

### 3. Geographic Location

Where you work matters—a lot. Welding salaries are heavily influenced by the cost of living and the concentration of specific industries. A TIG welder in a low-cost-of-living area might have more purchasing power than a higher-paid welder in an expensive city.

Top-Paying States for Welders (often driven by specific industries):

1. Alaska: ($70,000+) - Driven by oil, gas, and infrastructure maintenance.

2. North Dakota: ($68,000+) - Dominated by the energy sector (oil and gas pipelines).

3. Wyoming: ($65,000+) - Mining and energy industries.

4. District of Columbia: ($64,000+) - Federal and military contract work, infrastructure.

5. Hawaii: ($63,000+) - High cost of living and military/shipyard work.

States with High Demand and Strong Wages:

- Texas: A massive hub for oil & gas, manufacturing, and aerospace. Houston, in particular, is a hotbed for pipe and fabrication welders.

- Louisiana: Dominated by shipbuilding and offshore oil rig fabrication and repair.

- Washington: Home to Boeing and a massive aerospace supply chain, creating huge demand for skilled TIG welders.

- California: A diverse market with aerospace, defense contracting, and high-tech manufacturing.

- Pennsylvania: Strong in heavy manufacturing, power generation, and natural gas (Marcellus Shale).

Important Note on Location: High wages in states like Alaska and North Dakota are often tied to tough working conditions (extreme weather) and a "boom and bust" cycle. Stable, long-term careers are often found in more diversified industrial states like Texas, Washington, or Pennsylvania.

### 4. Industry and Area of Specialization

This is arguably the most impactful factor for a TIG welder. General fabrication is a great career, but specializing in a high-tech, high-stakes industry is the fastest path to a six-figure income.

- Aerospace: (Potential: $85,000 - $125,000+) This is the pinnacle for many TIG welders. You'll work with materials like titanium, aluminum, and Inconel, adhering to zero-failure tolerances. Certifications are extensive and demanding. Jobs are concentrated near major manufacturers like Boeing, Lockheed Martin, SpaceX, and their suppliers.

- Nuclear & Power Generation: (Potential: $80,000 - $120,000+, plus overtime/per diem) These roles involve welding on pressure vessels, piping, and turbines inside power plants. The work requires high levels of certification (ASME Section IX) and security clearance. Shutdown/maintenance work is particularly lucrative, with welders working long hours for a few weeks or months at a time, earning huge paychecks.

- Oil & Gas (Pipeline and Refinery): (Potential: $75,000 - $150,000+) TIG welding is used for the critical "root pass" on pipes to ensure a perfect, leak-proof seal. Traveling "rig welders" who own their own truck and equipment can earn some of the highest incomes in the entire trade, often exceeding $200,000 in a good year, though this comes with an entrepreneurial risk.

- Sanitary Welding (Food, Beverage, Pharmaceutical): (Potential: $65,000 - $90,000) This niche requires welding stainless steel tubing and vessels to a mirror-smooth finish on the inside to prevent any bacterial growth. It demands incredible precision and cleanliness.

- Motorsports & High-Performance Automotive: (Potential: $60,000 - $100,000) Welders in this field build custom roll cages, exhaust systems, and chassis components from materials like chromoly and titanium. It's a blend of technical skill and artistry, often found at race teams or specialty fabrication shops.

- Defense & Military Contracting: (Potential: $70,000 - $110,000) Similar to aerospace, this involves welding on armored vehicles, naval ships, and other military hardware. It requires high skill, specific certifications, and often a security clearance.

### 5. High-Value Ancillary Skills

Top-tier TIG welders are more than just welders; they are versatile fabricators. Developing skills that complement your welding ability makes you a more valuable asset and justifies a higher salary.

- Blueprint Reading & CAD: The ability to not just read, but deeply understand, complex blueprints is essential. Basic knowledge of CAD software (like AutoCAD or SolidWorks) to view and interpret 3D models is a huge plus.

- Metal Fabrication: Can you do more than just weld? Skills in cutting (plasma, laser), bending (press brake), shearing, and fitting make you a one-stop-shop fabricator.

- Metallurgy Knowledge: Understanding how different metals react to heat, the effects of pre-heating and post-weld heat treatment, and how to prevent issues like distortion and cracking is a high-level skill.

- Robotic & Automated Welding: While it may seem counterintuitive, welders who can program and operate automated welding systems (like robotic arms) are in high demand. This skill positions you to work alongside automation, not be replaced by it.

- Non-Destructive Testing (NDT): Having a basic understanding of or certification in NDT methods like dye penetrant testing (PT), magnetic particle testing (MT), or interpreting X-rays makes you invaluable to the quality control process.

By strategically developing your skills in these five areas, you can actively steer your career towards the most lucrative and rewarding opportunities in the TIG welding profession.

Job Outlook and Career Growth for TIG Welders

A high salary is attractive, but career stability and opportunities for advancement are what build long-term wealth and job satisfaction. For skilled TIG welders, the future looks bright and full of potential.

### The Numbers: Steady Demand Meets a Skills Gap

The U.S. Bureau of Labor Statistics projects that employment for welders, cutters, solderers, and brazers is expected to grow by 2 percent from 2022 to 2032. While this may seem modest, it translates to about 37,800 projected job openings each year, on average, over the decade.

Source: [BLS Occupational Outlook Handbook, Job Outlook section](https://www.bls.gov/ooh/production/welders-cutters-solderers-and-brazers.htm#tab-6)

The key insight from the BLS is where this demand comes from: "Many of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire."

This points to the single most significant factor in the welding job market: the skills gap. The American Welding Society (AWS) has projected a massive shortage of skilled welders in the coming years, potentially reaching a deficit of over 360,000 by 2027. A large portion of the current highly skilled workforce is approaching retirement age, and there are not enough new, qualified welders entering the field to replace them.

This is a classic supply and demand scenario. The supply of highly skilled TIG welders is shrinking, while the demand from advanced manufacturing, aerospace, and energy sectors remains robust. For a young, ambitious, and well-trained TIG welder, this translates directly into job security and increased bargaining power for higher wages.

### Emerging Trends and Future Opportunities

The world is changing, and so is the world of welding. Staying ahead of these trends will ensure your skills remain in high demand for decades to come.

- Infrastructure Investment: The nation's aging infrastructure—bridges, pipelines, power grids—requires constant maintenance, repair, and replacement. Federal and state infrastructure spending bills directly fund projects that require thousands of skilled welders. TIG welding is essential for the high-pressure pipe and structural work involved.

- Advanced Manufacturing & Reshoring: There is a growing trend of companies bringing manufacturing back to the United States ("reshoring"). These new, modern facilities rely on high-tech processes and, consequently, high-skill TIG welders to work on robotics, complex machinery, and specialized products.

- The Green Energy Revolution: The transition to renewable energy sources is creating new opportunities. Wind turbines have massive steel towers that require expert welding. The construction of nuclear power plants (a zero-emission energy source) and the development of hydrogen fuel infrastructure will rely heavily on specialized TIG pipe welders.

- Space Exploration: The commercial space industry, led by companies like SpaceX, Blue Origin, and Rocket Lab, is booming. Building rockets and spacecraft requires an incredible amount of precision TIG welding on exotic alloys that can withstand extreme temperatures and pressures. This is a frontier industry with a growing need for elite welders.

- Automation and Technology: Automation is not a threat to skilled TIG welders; it's a tool. While simple, repetitive welds may become automated, the complex, out-of-position, and critical welds will still require a human expert. Welders who embrace technology and learn to program and operate these robotic systems will become even more valuable, transitioning from manual artisans to high-tech