About the Author: With over 15 years of experience as a career analyst and professional development writer, I have guided thousands of individuals through the complexities of navigating technical career paths. My work focuses on providing data-driven, actionable advice to help professionals not only find a job but build a rewarding, future-proof career. This guide is the culmination of extensive research, industry analysis, and a deep understanding of what it takes to succeed in the skilled trades of the 21st century.

Introduction

Have you ever walked through a state-of-the-art manufacturing plant, a sprawling airport, or a modern skyscraper and marveled at the seamless coordination of it all? The lights, the climate control, the conveyor belts, the robotic arms—all operating in perfect harmony. This intricate dance of technology isn't magic; it's the work of a highly skilled professional operating behind the scenes: the Controls Technician. If you're a problem-solver who loves to understand how things work and thrives on the intersection of hardware and software, you might be looking at your future career.

A career as a Controls Technician is not just intellectually stimulating; it's also financially rewarding. This role is critical to the backbone of modern industry, and as automation and smart technology become more integrated into our world, the demand for these experts is only growing. While compensation varies, the national average for a Controls Technician salary typically falls between $65,000 and $85,000 per year, with entry-level positions starting around $55,000 and experienced, specialized senior technicians earning well over $100,000.

I remember touring a massive food and beverage packaging facility early in my career. I was struck by the sheer scale and speed of the operation. The guide pointed to a single technician calmly working on a laptop connected to a complex control panel. "That's Alex," he said. "The entire bottling line on this side of the plant shut down a minute ago. Without Alex, we'd be losing thousands of dollars every minute. He's the one who speaks the language of the machines." That moment solidified for me the immense value and hidden power of the controls profession. These technicians are the translators, the troubleshooters, and the guardians of our automated world.

This comprehensive guide will serve as your ultimate resource for understanding everything about a Controls Technician's career path. We will dissect salary expectations, explore the factors that can maximize your earnings, analyze the job outlook, and provide a step-by-step roadmap to get you started.

---

### Table of Contents

- [What Does a Controls Technician Do?](#what-they-do)

- [Average Controls Technician Salary: A Deep Dive](#salary-deep-dive)

- [Key Factors That Influence Salary](#key-factors)

- [Job Outlook and Career Growth](#job-outlook)

- [How to Get Started in This Career](#how-to-start)

- [Conclusion](#conclusion)

---

What Does a Controls Technician Do?

At its core, a Controls Technician is the hands-on expert responsible for the "nervous system" of automated equipment and systems. They install, calibrate, troubleshoot, maintain, and program the electronic controls that make machinery and processes run efficiently and safely. Think of a large industrial robot; the engineer might design its function, but the technician is the one on the floor ensuring its sensors are aligned, its movements are precise, and its software is running without errors.

Their work is a dynamic blend of electrical, mechanical, and software engineering principles. They are the bridge between the digital blueprint and the physical reality, ensuring that the theoretical design works flawlessly in the real world. This isn't a desk job; it's a role for those who enjoy being on their feet, using both their hands and their minds to solve complex puzzles.

Core Responsibilities and Daily Tasks:

A Controls Technician's duties can vary significantly depending on their industry and specialization, but the foundational responsibilities typically include:

- Installation and Commissioning: Wiring control panels, mounting sensors, installing programmable logic controllers (PLCs), and ensuring all components of a new system are set up according to engineering drawings and schematics.

- Programming and Configuration: Making modifications to PLC logic, configuring Human-Machine Interfaces (HMIs) so that operators can interact with the machinery, and adjusting parameters on Variable Frequency Drives (VFDs) to control motor speed.

- Troubleshooting and Repair: This is a critical part of the job. When a system fails, the Controls Technician is the first responder. They use diagnostic software, multimeters, and their deep system knowledge to identify the root cause—be it a faulty sensor, a loose wire, a software bug, or a mechanical failure—and implement a solution.

- Calibration and Maintenance: Performing preventative maintenance to ensure systems remain reliable. This involves calibrating sensors for accuracy (e.g., temperature, pressure, flow sensors), testing safety circuits, and updating software and firmware.

- Reading Technical Documents: Interpreting electrical schematics, P&ID (Piping and Instrumentation Diagrams), and technical manuals is a fundamental daily task.

- Documentation: Meticulously documenting all changes, repairs, and maintenance activities. This creates a historical record that is vital for future troubleshooting and regulatory compliance.

### A Day in the Life of a Controls Technician

To make this more concrete, let's imagine a day for "Sarah," a Mid-Career Controls Technician at a large automated distribution center:

- 8:00 AM: Sarah arrives and attends the morning shift-change meeting. The night shift reports a recurring fault on Conveyor Line 7, which is causing brief but costly stoppages. This is now her top priority.

- 8:30 AM: She heads to Line 7. Instead of just replacing the sensor that was faulting, she connects her laptop to the line's PLC. She analyzes the logic and historical fault logs, noticing the fault only occurs when a specific type of oversized box passes by.

- 10:00 AM: Her investigation reveals the photo-eye sensor is mounted just low enough that the corner of these oversized boxes momentarily blocks its view, tricking the system into thinking there's a jam. It's not a faulty part, but a design flaw in the sensor placement.

- 11:00 AM: After getting approval for a brief line stop, she works with a mechanic to fabricate a small extension bracket, moving the photo-eye up by two inches.

- 12:00 PM: Lunch.

- 1:00 PM: With Line 7 running smoothly, Sarah moves to her scheduled task for the day: performing quarterly preventative maintenance on the robotic palletizing system at the end of the shipping line. This involves checking motor voltages, cleaning optical sensors, and verifying the robot's safety interlocks are functioning correctly.

- 3:00 PM: An urgent call comes in. The HMI screen for the main sorting machine has gone blank. She rushes over, quickly diagnosing a failed power supply to the industrial PC running the interface. She retrieves a spare from inventory, replaces it, and has the system back online within 30 minutes.

- 4:30 PM: Sarah spends the last part of her day meticulously documenting the fix for Line 7 (including photos of the new bracket) and the HMI repair in the company's maintenance management system before heading home.

This example highlights the blend of detective work, hands-on repair, and preventative thinking that defines the role.

Average Controls Technician Salary: A Deep Dive

Now, let's get to the core of your query: compensation. The salary for a Controls Technician is highly competitive, reflecting the specialized skills and critical importance of the role. It's a profession where your expertise directly translates to higher earning potential. We will analyze data from several authoritative sources to build a clear and reliable picture of what you can expect to earn.

According to Salary.com, as of late 2023, the median annual salary for a Controls Technician in the United States is $76,423. The typical salary range falls between $66,244 and $86,964. However, this range can be much wider, with the bottom 10% earning around $57,000 and the top 10% of high-level technicians exceeding $97,000 in base salary alone.

Payscale.com reports a similar average base salary of approximately $70,084 per year, but provides a more detailed breakdown of total annual pay, which includes bonuses, profit sharing, and overtime. Their data shows that total pay can range from $49,000 to $102,000. This highlights a crucial point: overtime is a significant factor in a technician's total compensation, especially for those in manufacturing or field service roles who are often on call.

The U.S. Bureau of Labor Statistics (BLS) groups Controls Technicians under the broader category of "Electrical and Electronics Engineering Technologists and Technicians." For this group, the median annual wage was $70,000 as of May 2022. The lowest 10 percent earned less than $45,780, and the highest 10 percent earned more than $103,500. This government data reinforces the ranges provided by salary aggregators and confirms the strong earning potential for top performers.

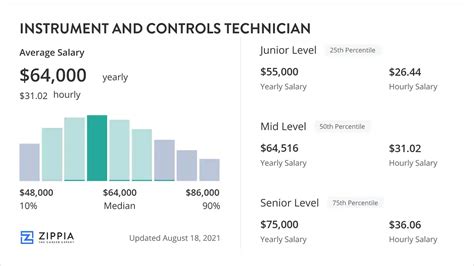

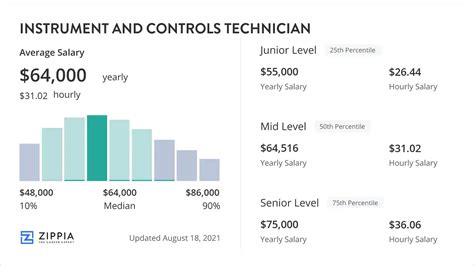

### Salary by Experience Level

Your experience is one of the single most significant drivers of your salary. As you gain expertise in troubleshooting complex systems and programming different platforms, your value to an employer skyrockets.

Here is a typical salary progression you can expect throughout your career, compiled from a blend of data from Salary.com, Payscale, and industry observations:

| Experience Level | Years of Experience | Typical Annual Base Salary Range | Key Responsibilities & Skills |

| :--- | :--- | :--- | :--- |

| Entry-Level Controls Technician | 0-2 Years | $55,000 - $68,000 | Assisting senior technicians, performing basic calibrations, wiring panels, learning to read schematics, basic PLC/HMI edits. |

| Mid-Career Controls Technician | 2-9 Years | $68,000 - $85,000 | Independent troubleshooting, leading small installation projects, programming PLC logic from scratch, VFD configuration, system commissioning. |

| Senior/Lead Controls Technician | 10+ Years | $85,000 - $110,000+ | Designing control systems, mentoring junior technicians, managing complex automation projects, specializing in high-demand areas (robotics, SCADA), optimizing system performance. |

### Beyond the Base Salary: Understanding Total Compensation

Your paycheck is more than just your base salary. A comprehensive compensation package for a Controls Technician often includes several other valuable components:

- Overtime Pay: As mentioned, this can be a massive part of total earnings. In 24/7 manufacturing or mission-critical environments (like data centers), technicians are often required to work overtime to resolve issues, and this is paid at a premium rate (typically 1.5x the hourly wage).

- Bonuses: Many companies offer annual performance-based bonuses, which can range from a few thousand dollars to 10-15% of your base salary for senior roles.

- Profit Sharing: Some manufacturing companies share a portion of their profits with employees, providing an additional yearly payout that is tied to the company's success.

- Per Diem and Travel Pay: Field service technicians who travel to customer sites often receive a daily allowance (per diem) to cover meals and expenses, in addition to their regular pay. This can add a significant untaxed amount to their income.

- Company Vehicle and Tools: A company truck or van is a common perk for field technicians, saving them thousands per year on personal vehicle wear and tear. Many companies also provide a generous tool allowance or supply all necessary specialized equipment.

- Benefits Package: Don't underestimate the value of a strong benefits package. This includes health, dental, and vision insurance; a 401(k) or pension plan with a company match; paid time off; and disability insurance. A robust package can be worth an additional $15,000 - $25,000 per year in value.

- Tuition Reimbursement & Professional Development: Many forward-thinking companies will pay for you to pursue further education or gain valuable certifications, investing in your growth as a way to retain top talent.

When evaluating a job offer, it's crucial to look at this complete picture of total compensation, not just the base salary figure.

Key Factors That Influence Controls Technician Salary

While the national averages provide a great starting point, your personal earning potential is determined by a combination of specific factors. Understanding and strategically developing these areas can add tens of thousands of dollars to your annual salary over the course of your career. This section is the most critical for anyone looking to maximize their income in the controls field.

###

Level of Education and Certification

While you don't necessarily need a four-year bachelor's degree to become a successful Controls Technician, your educational background forms the foundation of your career and salary.

- High School Diploma / GED: This is the absolute minimum requirement. Individuals starting here often enter the field through apprenticeships or as an "operator" and work their way up, but the path is longer and initial pay is lower.

- Vocational School or Certificate Program: A 1-2 year program focused on industrial maintenance, electronics, or electromechanical technology provides a strong, hands-on foundation. Graduates are more attractive to employers and can command higher starting salaries than those with only a high school diploma.

- Associate of Applied Science (A.A.S.) Degree: This is often considered the "sweet spot" for entering the controls field. A two-year degree in Automation & Controls Technology, Mechatronics, or Electronics Engineering Technology from a community college is highly valued. It combines theoretical knowledge with extensive lab work, preparing graduates to hit the ground running. Starting salaries for those with an A.A.S. are typically at the higher end of the entry-level range.

- Bachelor's Degree (B.S.): While a B.S. in Electrical or Mechanical Engineering can lead to a controls position, it often puts a candidate on a path toward a Controls *Engineer* role. Engineers focus more on system design, project management, and high-level programming, while technicians are more hands-on with implementation and troubleshooting. An engineering degree can lead to a higher salary ceiling, but the day-to-day job is different.

The Power of Certifications:

In the world of controls, professional certifications are a direct way to prove your expertise and increase your paycheck. They are a clear signal to employers that you have a verified, standardized level of knowledge.

- ISA Certified Control Systems Technician (CCST®): This is the gold standard certification for controls professionals. Offered by the International Society of Automation (ISA), it has three levels (I, II, and III) that correspond to experience and knowledge. Earning a CCST designation can significantly boost your resume and salary negotiations. Many companies require or strongly prefer CCST-certified technicians for senior roles.

- Vendor-Specific Certifications: Becoming certified on specific equipment platforms is extremely valuable. For example:

- Rockwell Automation (Allen-Bradley): Certifications in programming PLCs (Logix5000), HMIs (FactoryTalk View), and motion control are highly sought after in North American manufacturing.

- Siemens: Expertise in the Siemens TIA Portal and S7 PLCs is in high demand, particularly in industries with European-made equipment.

- Schneider Electric, Beckhoff, Omron: Certifications from other major automation vendors can make you a specialist in certain niches.

- Networking Certifications: As control systems become more networked, certifications like CompTIA Network+ or Cisco's CCNA can differentiate you, especially in roles that involve managing industrial networks like EtherNet/IP or PROFINET.

###

Years of Experience

As illustrated in the salary table, experience is paramount. However, it's not just about the number of years, but the *quality* and *variety* of that experience.

- Early Career (0-4 years): Salary growth is often rapid in this phase as you move from being a trainee to a competent, independent technician. Each year brings new skills and a demonstrable increase in your ability to solve problems, which should be reflected in your pay. Annual salary increases in the 5-10% range are not uncommon, either through raises or by changing jobs.

- Mid-Career (5-15 years): In this stage, you become a go-to expert. Your salary growth is driven by taking on more complex challenges. Have you led a major machine installation? Have you designed and implemented a new control panel from scratch? Have you become the site expert on the robotic systems? This is where you transition from simply *fixing* problems to *preventing* them and *improving* systems. Salaries in this bracket, especially for those with 10+ years of experience, push into the $85,000 to $100,000 range.

- Late Career / Senior Expert (15+ years): Top-tier technicians at this level are masters of their craft. They often move into lead or supervisory roles, mentoring others and managing the entire controls strategy for a plant or facility. Others become highly specialized consultants or field service experts for a specific technology (e.g., a high-end vision system or a complex drive system), commanding salaries well over $110,000, particularly with overtime and bonuses.

###

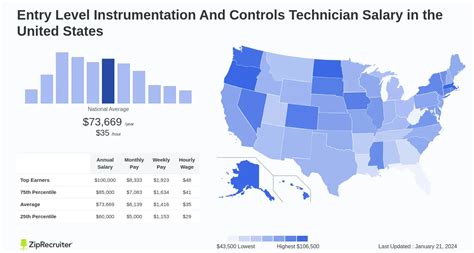

Geographic Location

Where you work has a major impact on your salary. A higher salary in a major city, however, must always be weighed against a higher cost of living.

Here's a breakdown of how location can affect a Controls Technician's salary, with data sourced from Glassdoor and Salary.com analyses in late 2023:

Top-Paying States (and contributing factors):

1. California: Particularly in areas like the Bay Area and Southern California, the confluence of high-tech manufacturing, data centers, and a high cost of living drives salaries up. Average salaries can be 15-25% higher than the national average.

2. Alaska: The oil and gas industry and remote work conditions lead to significant pay premiums to attract skilled technicians.

3. Washington: A strong manufacturing and aerospace sector (Boeing and its suppliers) and a burgeoning tech/data center industry around Seattle create high demand.

4. Massachusetts: The biotech, pharmaceutical, and robotics industries around Boston pay a premium for top-tier controls talent.

5. Texas: The massive oil and gas sector, along with a huge manufacturing base in cities like Houston, Dallas, and Austin, creates a very large and competitive market for technicians.

Metropolitan Areas with High Salaries:

- San Jose, CA

- Houston, TX

- Boston, MA

- Seattle, WA

- Washington, D.C. (especially for data centers and government facilities)

States with Salaries Closer to or Below the National Average:

Salaries tend to be lower in the Southeast and parts of the Midwest, outside of major industrial hubs. However, the lower cost of living in these areas can mean your take-home pay goes much further. States like Mississippi, Arkansas, South Carolina, and Alabama may offer lower base salaries but could provide a better overall quality of life depending on your personal financial situation.

###

Company Type & Size

The type of company you work for will shape your salary, benefits, and day-to-day experience.

- Large Corporations / Fortune 500 Manufacturers (e.g., Procter & Gamble, Tesla, General Motors):

- Pros: Typically offer the highest base salaries and most comprehensive benefits packages (excellent health insurance, 401k matching, pensions). They have structured pay grades, clear career paths, and significant investment in training.

- Cons: Roles can be highly specialized (you might only work on one type of machine). Bureaucracy can sometimes slow down decision-making.

- System Integrators: These are companies that design, build, and install automated systems for other companies.

- Pros: You will be exposed to a huge variety of technologies, platforms, and industries, accelerating your learning at an incredible rate. Pay is often very competitive, and there can be significant travel and overtime opportunities.

- Cons: The work can be high-pressure with tight deadlines. Travel can be extensive, which may not be suitable for everyone.

- Small to Medium-Sized Businesses (SMBs):

- Pros: You will likely wear many hats, giving you a broad range of experience. There is often a more direct connection to the company's success and a more flexible, familial culture.

- Cons: Salaries and benefits might not be as high as at large corporations. Training might be more on-the-job rather than through formal programs.

- Government and Public Utilities (e.g., Water Treatment Plants, Power Generation, Municipalities):

- Pros: Excellent job security, great work-life balance, and often fantastic pension and benefits packages.

- Cons: Salaries may not reach the highest peaks seen in private industry. Technology adoption can sometimes be slower, and processes can be more rigid due to regulations.

###

Area of Specialization

Just as doctors specialize, so do Controls Technicians. Developing expertise in a high-demand niche is one of the most effective ways to become a top earner. The query mentioned "IT vs. marketing vs. finance," which doesn't directly apply, but the principle of specialization is key. Here are the relevant specializations for a controls professional:

- Manufacturing & Industrial Automation (PLCs/Robotics): This is the most common specialization. Technicians who are experts in programming and troubleshooting PLCs (especially Allen-Bradley and Siemens) and industrial robots (FANUC, KUKA, ABB) are the bedrock of modern manufacturing. This field offers a vast number of jobs and strong salaries.

- Building Automation Systems (BAS / BMS): These technicians specialize in the control systems for large commercial buildings, managing HVAC, lighting, security, and energy management. As "green" buildings and energy efficiency become more critical, the demand and pay for skilled BAS technicians are rising sharply. Expertise in platforms like Johnson Controls Metasys, Schneider's Ecostruxure, or Trane's Tracer is highly valuable.

- Data Center Operations: Data centers are the physical heart of the internet, and they require 100% uptime. Controls Technicians in this field (often called "Data Center Engineering Operations Technicians") manage the incredibly complex power distribution and cooling systems. Due to the mission-critical nature of the work, these roles often come with a significant salary premium.

- Water/Wastewater: This specialization involves managing the SCADA (Supervisory Control and Data Acquisition) systems that control the entire process of water treatment and distribution. It offers incredible job stability and government-level benefits.

- Pharmaceutical/Biotech: Working in this highly regulated environment requires a deep understanding of compliance (e.g., FDA 21 CFR Part 11). Technicians must be meticulous with documentation and calibration. This added layer of complexity and responsibility commands a higher salary.

- Field Service: Field Service Technicians work for an equipment manufacturer or system integrator and travel to customer sites to perform installations, commissioning, and emergency repairs. This lifestyle involves a lot of travel, but it often comes with the highest earning potential due to overtime, per diems, and the high-level expertise required.

###

In-Demand Skills

Beyond general competence, possessing specific, high-value technical skills can make you a top candidate and justify a higher salary. If you see these skills in a job description, it's often a sign of a more advanced (and better-paying) role.

- PLC Programming: This is the most fundamental skill. Simply being able to troubleshoot is good, but being able to write, modify, and optimize complex PLC logic (in formats like Ladder Logic, Structured Text, or Function Block Diagram) is what separates the top earners.

- HMI & SCADA Development: The ability to design and configure intuitive graphical interfaces for operators is crucial. Experts in SCADA platforms like Ignition, Wonderware, or FactoryTalk View SE are in constant demand.

- Robotics Integration and Programming: As robots become ubiquitous, technicians who can install, program (teach pendants), and troubleshoot robotic arms are at the top of the pay scale.

- Industrial Networking: A deep understanding of industrial network protocols like EtherNet/IP, PROFINET, Modbus TCP/IP, and the ability to troubleshoot network issues is a massive advantage.

- Variable Frequency Drives (VFDs): Expertise in configuring, tuning, and troubleshooting VFDs for motor control is a core competency.

- Instrumentation and Calibration: Precise knowledge of how to install and calibrate various instruments (pressure, temperature, flow, level sensors) is critical, especially in process industries.

- Electrical and Electronic Troubleshooting: The ability to read electrical schematics and safely use a multimeter to diagnose issues down to the component level is a non-negotiable skill that commands respect and higher pay.

- Cybersecurity for Industrial Control Systems (ICS): This is an emerging and highly valuable skill. Understanding how to secure control systems from cyber threats is becoming a major priority for companies.

Job Outlook and Career Growth

When choosing a career, long-term stability and growth opportunities are just as important as the initial salary. For Controls Technicians, the