In the intricate world of modern manufacturing, few roles are as critical or require as much precision as that of a tool and die maker. These highly skilled professionals are the architects of the industrial process, creating the specialized tools, dies, jigs, and molds that shape everything from car parts to surgical instruments. If you're considering this rewarding career path, one of your primary questions is likely about compensation.

This article provides a data-driven look at the salary you can expect as a tool and die maker in the United States. A career in this field offers not just the satisfaction of tangible craftsmanship but also a stable and competitive income, with typical salaries ranging from $50,000 for entry-level apprentices to over $85,000 for experienced specialists in high-demand industries.

What Does a Tool and Die Maker Do?

Tool and die makers are the master craftspeople of the manufacturing world. They are responsible for producing and maintaining the precision tools, dies, and other fixtures that enable mass production. Their work is a sophisticated blend of traditional hands-on skill and modern computer-aided technology.

Key responsibilities include:

- Reading and interpreting complex blueprints and technical schematics.

- Using Computer-Aided Design (CAD) software to design tools and dies.

- Programming and operating Computer-Numerical Control (CNC) machines, as well as traditional machinery like lathes, milling machines, and grinders.

- Measuring and checking finished products to ensure they meet exacting specifications, often within ten-thousandths of an inch.

- Assembling, fitting, and repairing tools, dies, and molds.

Essentially, if a product is mass-produced, a tool and die maker was essential to creating the machinery that made it possible.

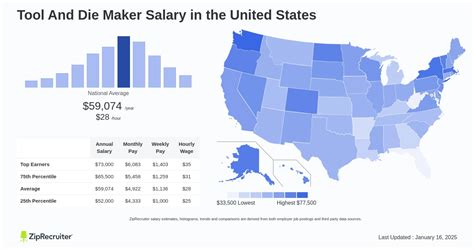

Average Tool and Die Maker Salary

The compensation for a tool and die maker reflects the high level of skill and precision required for the job. While salaries vary, we can establish a clear picture by looking at data from leading authoritative sources.

According to the U.S. Bureau of Labor Statistics (BLS), the median annual wage for tool and die makers was $60,930 in May 2023. This means half of all tool and die makers earned more than this amount, and half earned less. The BLS data also provides a broader perspective on the salary range:

- Lowest 10%: Earned less than $40,650

- Highest 10%: Earned more than $84,180

Reputable salary aggregators, which collect real-time, user-reported data, often show slightly higher averages. For example, Salary.com places the median salary for a Tool and Die Maker II (a mid-career professional) around $70,500, with a typical range falling between $62,000 and $80,000. Similarly, data from Payscale and Glassdoor consistently place the average base salary in the $65,000 to $72,000 range.

This data paints a clear picture: a tool and die maker can expect to earn a solid, middle-class to upper-middle-class income that grows significantly with expertise.

Key Factors That Influence Salary

Your specific salary as a tool and die maker isn't just one number; it’s a dynamic figure influenced by several key factors. Understanding these variables can help you maximize your earning potential throughout your career.

### Level of Education

While a four-year university degree is not required, your educational background and formal training are paramount. The most common pathway is a multi-year apprenticeship program that combines on-the-job training with classroom instruction. Those who supplement their apprenticeship with an associate's degree in machine tool technology or a related field can often command higher starting salaries. Furthermore, holding certifications in specific skills—such as CNC programming, geometric dimensioning and tolerancing (GD&T), or specific CAD/CAM software (like Mastercam or SolidWorks)—is a direct lever for increased pay.

### Years of Experience

Experience is arguably the most significant factor in a tool and die maker's salary. As you progress from an apprentice to a journeyman and eventually to a senior or lead position, your value—and your paycheck—grows substantially.

- Entry-Level / Apprentice (0-3 years): In the early stages, expect a salary in the $45,000 to $55,000 range. The focus is on learning the trade under the supervision of experienced mentors.

- Mid-Career / Journeyman (4-10 years): With a solid foundation of skills, your earning potential increases to the $60,000 to $75,000 range. You can work independently on complex projects.

- Senior / Lead (10+ years): Seasoned experts with deep knowledge and leadership abilities can earn $75,000 to $90,000 or more. These professionals often supervise teams, tackle the most challenging projects, or specialize in high-value areas.

### Geographic Location

Where you work matters. States with a strong manufacturing base tend to offer more opportunities and higher wages to attract top talent. According to BLS data, the top-paying states for tool and die makers include:

- Michigan

- Washington

- Wisconsin

- Indiana

- Ohio

Metropolitan areas with concentrations of aerospace, automotive, or medical device manufacturing often provide the highest salaries. However, it's essential to balance higher wages against the local cost of living.

### Company Type

The industry and size of the company you work for can have a major impact on your salary. The BLS reports that tool and die makers in the Aerospace Product and Parts Manufacturing industry earn one of the highest average salaries. Other high-paying sectors include Motor Vehicle Parts Manufacturing and Metalworking Machinery Manufacturing. Large, unionized corporations in these sectors often offer more competitive wages, benefits, and overtime opportunities than smaller, independent job shops.

### Area of Specialization

Within the field, certain specializations are more complex and command higher pay.

- Diemaker: Focuses on creating stamping dies for sheet metal parts, common in the automotive industry.

- Toolmaker: Builds and maintains jigs, fixtures, and other cutting or machining tools.

- Mold Maker: Specializes in creating highly intricate injection molds for plastics. This is often considered one of the most demanding and highest-paying specializations due to the extreme precision required.

Professionals who develop expertise in multi-axis CNC machining, advanced metrology (measurement), or the design and construction of progressive dies are particularly valuable and can expect to be at the top of the pay scale.

Job Outlook

The U.S. Bureau of Labor Statistics projects that employment for machinists and tool and die makers will see a slight decline of 1 percent from 2022 to 2032. However, this statistic requires important context.

While automation is streamlining some routine tasks, it is simultaneously increasing the demand for highly skilled tool and die makers who can program, set up, and maintain the sophisticated automated equipment. Furthermore, a significant portion of the current workforce is approaching retirement age, creating a skills gap. This means that while overall numbers may be flat, there will be consistent demand and excellent opportunities for well-trained, tech-savvy individuals entering the field.

Conclusion

A career as a tool and die maker is an excellent choice for individuals who possess mechanical aptitude, a passion for precision, and a desire to see their work's tangible results. The profession offers a rewarding and stable career path with significant earning potential.

Key Takeaways:

- Strong Earning Potential: Expect a median salary between $60,000 and $72,000, with senior specialists earning over $85,000.

- Experience is King: Your salary will grow significantly as you gain experience and move from apprentice to journeyman to lead maker.

- Skills Pay the Bills: Specializing in high-demand areas like mold making or advanced CNC programming will maximize your income.

- Stable Demand: Despite automation, the need for skilled professionals to manage advanced technology and replace a retiring workforce ensures strong prospects for new talent.

For those dedicated to mastering the craft, becoming a tool and die maker is not just a job—it's a gateway to a respected, challenging, and well-compensated profession at the very heart of modern industry.