Introduction

In the intricate dance of modern technology, where mechanical gears meet electrical circuits, a unique and indispensable professional stands at the center: the electromechanical engineering technician. Imagine the sophisticated robotic arm on a vehicle assembly line, the complex diagnostic equipment in a hospital, or the automated sorting systems in a massive distribution center. These marvels of innovation are not self-sustaining; they are built, tested, maintained, and repaired by the skilled hands and sharp minds of these technicians. They are the unsung heroes who translate complex engineering designs into tangible, functioning reality, ensuring the seamless operation of the automated world around us.

If you are a problem-solver at heart, someone who finds deep satisfaction in understanding how things work and making them better, a career as an electromechanical engineering technician could be an incredibly rewarding path. It’s a field that offers not just intellectual stimulation and hands-on work, but also a stable and lucrative career. The national median salary for this profession hovers around a competitive $67,830 per year, with top earners reaching well over $100,000 annually.

I remember touring a semiconductor fabrication plant years ago, a cleanroom environment that felt like stepping into the future. Behind glass, robotic wafers zipped along overhead tracks with silent, precise movements. My guide pointed to a technician in a full "bunny suit" working diligently on a complex piece of photolithography equipment. "That person," he said, "is the reason millions of dollars of product will ship on time this week. When this machine has a hiccup, they're the surgeon who fixes it." That moment solidified my understanding of this role's critical importance—it's where the theoretical power of engineering meets the practical needs of industry.

This comprehensive guide is designed to be your definitive resource for understanding the financial landscape of an electromechanical engineering technician career. We will delve deep into salary data, explore the critical factors that influence your earning potential, and provide a clear, step-by-step roadmap to get you started.

### Table of Contents

- [What Does an Electromechanical Engineering Technician Do?](#what-does-an-electromechanical-engineering-technician-do)

- [Average Electromechanical Engineering Technician Salary: A Deep Dive](#average-electromechanical-engineering-technician-salary-a-deep-dive)

- [Key Factors That Influence Salary](#key-factors-that-influence-salary)

- [Job Outlook and Career Growth](#job-outlook-and-career-growth)

- [How to Get Started in This Career](#how-to-get-started-in-this-career)

- [Conclusion](#conclusion)

What Does an Electromechanical Engineering Technician Do?

At its core, an electromechanical engineering technician is a professional who bridges the gap between mechanical engineering and electrical/electronic engineering. They work with devices and systems that combine both domains, often referred to as "mechatronics." Their work is hands-on, detail-oriented, and centered on problem-solving. They are the individuals responsible for ensuring that the complex machinery that powers modern manufacturing, automation, robotics, and countless other industries functions correctly, efficiently, and safely.

Their responsibilities are diverse and can vary significantly depending on the industry and specific employer. However, the core duties typically revolve around the entire lifecycle of electromechanical equipment.

Core Responsibilities and Daily Tasks:

- Assembly and Installation: Technicians meticulously assemble new automated or robotic systems based on blueprints, schematics, and engineering specifications. This can range from building a small prototype for a new product to installing a large-scale industrial robot on a factory floor.

- Testing and Validation: Once a system is built, it must be thoroughly tested. Technicians run diagnostic tests and simulations to ensure all components—motors, sensors, controllers, and software—are working together as designed. They document performance, calibrate instruments, and verify that the system meets all quality and safety standards.

- Maintenance and Repair: This is a crucial part of the job. Technicians perform preventative maintenance to keep equipment running smoothly and prevent costly downtime. When a machine malfunctions, they are the first responders. They use their expertise and sophisticated diagnostic tools (like multimeters and oscilloscopes) to troubleshoot the problem, identify the faulty component (whether it's a worn-out gear or a fried circuit board), and perform the necessary repairs.

- Troubleshooting and Analysis: They are expert detectives for machines. They analyze system failures, read error logs, and use a logical process of elimination to get to the root cause of a problem. This requires a deep understanding of both mechanical principles (like hydraulics and pneumatics) and electrical principles (like circuit theory and PLC logic).

- Documentation and Reporting: Precision is key. Technicians maintain detailed records of tests, repairs, and maintenance schedules. They write reports on system performance and may suggest modifications to engineers to improve a product's design, efficiency, or reliability.

### A Day in the Life: Example

To make this role more tangible, let’s walk through a hypothetical day for an electromechanical technician working at a modern manufacturing plant.

- 8:00 AM: The day begins with a team huddle with the shift supervisor and engineers. They review the production schedule and discuss any ongoing issues. A recurring fault has been noted on the robotic arm on Assembly Line 3, and it's assigned as the top priority.

- 8:30 AM: The technician heads to Line 3. After consulting the operator and reviewing the machine's error logs, they observe the robotic arm in action. They notice a slight hesitation and inconsistency in its movement, which wasn't present yesterday.

- 9:15 AM: Following safety lockout/tagout procedures, they power down the machine. They begin a systematic inspection, checking the mechanical joints for wear and the electrical connections for any looseness. Using a multimeter, they test the voltage going to the servo motor that controls the primary joint. The reading is unstable.

- 11:00 AM: Tracing the wiring back, they identify a frayed cable near a high-friction point. This intermittent connection is likely the cause of the erratic motor behavior. They document the finding with a photo, remove the damaged cable, and carefully install a replacement, ensuring it's routed to prevent future wear.

- 1:00 PM: After a lunch break, they power the system back on. They run the robot through a series of diagnostic and calibration routines, closely monitoring its performance. The movement is now smooth and precise.

- 2:30 PM: They work with the quality control team to run a test batch of products through Line 3, confirming that the fix has resolved the issue and production quality is back to standard.

- 3:30 PM: The technician logs the entire process in the company's computerized maintenance management system (CMMS). They detail the problem, the root cause, the corrective action taken, and the parts used. They also add a recommendation to the preventative maintenance schedule to inspect that specific cable every 500 hours of operation.

- 4:30 PM: They spend the last part of their day working with an engineer to assemble and test a new sensor array for a future product line, providing practical feedback on the assembly process before it's finalized.

This "day in the life" showcases the blend of analytical thinking, hands-on skill, and communication that defines the role of an electromechanical engineering technician.

Average Electromechanical Engineering Technician Salary: A Deep Dive

One of the most compelling aspects of a career as an electromechanical engineering technician is the strong and competitive compensation package. This field rewards technical expertise and practical skill with a salary that provides a comfortable living and significant growth potential. Let's break down the numbers from the most reliable sources.

### National Salary Averages and Ranges

The most authoritative source for occupational data in the United States is the U.S. Bureau of Labor Statistics (BLS). According to the BLS's May 2023 Occupational Employment and Wage Statistics report for "Electro-Mechanical and Mechatronics Technologists and Technicians" (SOC Code 17-3024), the national salary landscape is as follows:

- Median Annual Wage: $67,830

- This means that 50% of all technicians in the U.S. earned more than this amount, and 50% earned less. This is often the most accurate representation of a "typical" salary.

- Mean Annual Wage: $69,360

- This is the average salary, which can be slightly skewed by very high earners.

- Salary Range (Percentiles):

- Bottom 10%: Earned less than $45,390 (typically entry-level positions or roles in lower-paying regions/industries).

- 25th Percentile: $55,170

- 75th Percentile: $82,310

- Top 10%: Earned more than $101,000 (highly experienced technicians, specialists in high-demand fields, or those in senior/supervisory roles).

Reputable salary aggregator websites provide a similar picture, often using user-reported data that can offer real-time insights.

- Salary.com (as of early 2024) reports the median salary for an Electromechanical Technician I (entry-level) at $61,862, while a more experienced Electromechanical Technician III is listed with a median of $79,835. Their data shows a typical range spanning from $53,000 to over $90,000.

- Payscale.com (as of early 2024) places the average base salary at $64,481 per year, with a reported range from $46,000 to $91,000.

- Glassdoor (as of early 2024) estimates the total pay (including base and additional pay like bonuses) to be around $73,634 per year on average.

The consistency across these data sources paints a clear picture: this is a well-compensated, middle-class career with a very respectable earning ceiling for top performers.

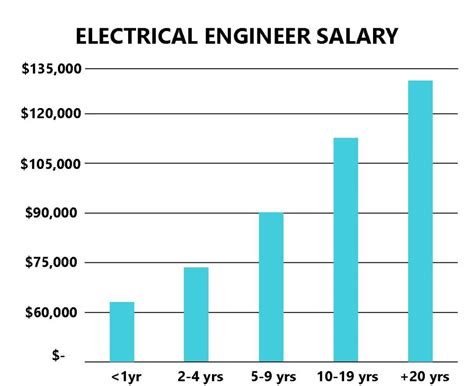

### Salary by Experience Level

As with any profession, experience is a primary driver of salary growth. As a technician gains skills, becomes more independent, and takes on more complex responsibilities, their value to an employer—and their paycheck—increases significantly.

Here’s a typical salary progression based on experience level, compiled from BLS and salary aggregator data:

| Experience Level | Years of Experience | Typical Annual Salary Range | Key Responsibilities & Skills |

| ------------------- | ------------------- | ------------------------------ | -------------------------------------------------------------------------------------------------------------- |

| Entry-Level | 0-2 years | $45,000 - $60,000 | Basic assembly from blueprints, running predefined tests, routine maintenance, assisting senior technicians. |

| Mid-Career | 3-8 years | $60,000 - $80,000 | Independent troubleshooting, complex repairs, system calibration, PLC/HMI modifications, training junior staff. |

| Senior/Experienced | 9+ years | $80,000 - $101,000+ | Leading complex projects, designing test procedures, system optimization, mentoring teams, failure analysis. |

This table illustrates a clear and rewarding path for advancement. A dedicated technician can potentially double their starting salary over the course of their career through skill development and proven performance.

### Beyond the Base Salary: Understanding Total Compensation

Your annual salary is only one part of the financial equation. Electromechanical technician roles often come with additional forms of compensation that significantly boost total earnings.

- Overtime Pay: This is a major factor. Manufacturing and industrial settings often run 24/7. When a critical machine goes down, technicians are often required to work overtime to get it back online. This work is typically paid at 1.5 times the regular hourly rate (or more), which can add a substantial amount to an annual income.

- Bonuses: Many companies, especially in manufacturing and R&D, offer performance-based bonuses. These can be tied to individual performance, team goals (e.g., meeting uptime targets), or overall company profitability. Annual bonuses can range from a few thousand dollars to 10% or more of the base salary.

- Profit Sharing: Some companies offer profit-sharing plans, where a portion of the company's profits is distributed among employees. This directly links your compensation to the success of the business.

- Benefits Package: The value of a strong benefits package cannot be overstated. This is part of your total compensation. Look for:

- Health Insurance: Comprehensive medical, dental, and vision plans. A good plan can be worth over $10,000 per year.

- Retirement Savings: 401(k) or 403(b) plans, especially those with a generous company match. A company that matches your contributions is essentially giving you a guaranteed return on your investment.

- Paid Time Off (PTO): Includes vacation days, sick leave, and paid holidays.

- Tuition Reimbursement: Many employers will pay for continuing education, such as certifications or even a bachelor's degree, which is a direct investment in your future earning power.

- Tool Allowance: Some companies provide a yearly allowance for technicians to purchase or upgrade their own hand tools.

When evaluating a job offer, it's crucial to look beyond the base salary and consider the full value of the total compensation package.

Key Factors That Influence Salary

While the national averages provide a great baseline, your specific salary as an electromechanical engineering technician will be determined by a combination of powerful factors. Understanding these variables is the key to negotiating a better salary and strategically guiding your career for maximum earning potential.

###

Level of Education and Certifications

Your educational foundation is the launching pad for your career and a significant determinant of your starting salary and long-term growth.

- Associate's Degree: The most common and widely accepted educational path is an Associate of Applied Science (A.A.S.) in Electromechanical Technology or Mechatronics. This two-year degree provides the perfect blend of theoretical knowledge (mathematics, physics, electronics) and intensive hands-on lab experience (PLCs, robotics, hydraulics). Graduates with an A.A.S. are highly sought after and can command strong starting salaries.

- Certificate Programs: One-year certificate programs are a faster way to enter the field. They are highly focused on practical skills but may offer less of the foundational theory than an associate's degree. While they can get you in the door, your starting salary may be slightly lower, and you might need more on-the-job training to advance to higher levels.

- Bachelor's Degree: While not typically required for technician roles, a Bachelor of Science in Electromechanical Engineering Technology (EMET) or a related field opens doors to higher-level positions and significantly higher pay. Graduates can start in roles like Controls Engineer, Automation Engineer, or Field Service Engineer, which often have starting salaries that overlap with what senior technicians earn. It's a common pathway for ambitious technicians seeking to move into engineering or management.

- Professional Certifications: Certifications are a powerful tool for demonstrating specialized expertise and boosting your salary. They are third-party validations of your skills. Key certifications that can lead to higher pay include:

- PMMI Mechatronics Certifications: Offered by the Association for Packaging and Processing Technologies, these are highly respected in the manufacturing and automation industries. They cover areas like industrial electricity, mechanical components, PLCs, and robotics.

- Certified Engineering Technician (CET): Offered by the National Institute for Certification in Engineering Technologies (NICET), this is a widely recognized credential that demonstrates a broad base of competency.

- Manufacturer-Specific Certifications: Becoming certified by major equipment manufacturers like Rockwell Automation (Allen-Bradley), Siemens, FANUC (robotics), or KUKA (robotics) makes you an invaluable asset to any company using their equipment. These certifications often lead directly to pay bumps and specialized roles.

###

Years of Experience

Experience is arguably the single most important factor in salary growth for a technician. Theoretical knowledge is essential, but the ability to quickly and accurately diagnose a real-world problem on a complex machine is a skill honed only through years of practice.

- Entry-Level (0-2 Years): At this stage, you are applying your education under supervision. You'll focus on learning company procedures, performing routine tasks, and assisting senior technicians. Your salary will be in the $45,000 to $60,000 range, reflecting your status as a trainee. The focus here is on absorbing as much knowledge as possible.

- Mid-Career (3-8 Years): You have now become a reliable, independent problem-solver. You are trusted to handle complex troubleshooting tasks on your own, may be responsible for specific production lines or equipment, and might start training new hires. Your salary will see a significant jump into the $60,000 to $80,000 range as your proven value increases. You can confidently lead small projects and suggest process improvements.

- Senior/Lead Technician (9+ Years): With nearly a decade or more of experience, you are a subject matter expert. You tackle the most difficult and unusual problems that stump others. You may be involved in the design and implementation of new automated systems, lead a team of technicians, manage the maintenance department's budget, or specialize in a high-value area like system optimization or failure analysis. Your salary will reflect this expertise, pushing into the $80,000 to $101,000+ range, especially if you have supervisory responsibilities.

###

Geographic Location

Where you work matters—a lot. Salaries can vary dramatically from state to state and even from one metropolitan area to another, largely due to differences in the cost of living and the concentration of high-paying industries.

According to the May 2023 BLS data, the top-paying states for electromechanical and mechatronics technicians are:

1. New Mexico: Annual Mean Wage: $86,700

2. Washington: Annual Mean Wage: $80,210

3. California: Annual Mean Wage: $79,890

4. Maryland: Annual Mean Wage: $79,590

5. Arizona: Annual Mean Wage: $77,410

Conversely, some of the lower-paying states include West Virginia, Mississippi, and South Dakota, where the mean wage can be closer to the $50,000-$55,000 range.

The differences are even more pronounced at the metropolitan level. High-tech hubs and areas with significant manufacturing or R&D presence offer the highest salaries. Here are some of the top-paying metropolitan areas:

1. San Jose-Sunnyvale-Santa Clara, CA (Silicon Valley): Annual Mean Wage: $98,150

2. Albuquerque, NM: Annual Mean Wage: $89,610

3. Santa Maria-Santa Barbara, CA: Annual Mean Wage: $87,270

4. San Francisco-Oakland-Hayward, CA: Annual Mean Wage: $86,510

5. Seattle-Tacoma-Bellevue, WA: Annual Mean Wage: $82,230

It is crucial, however, to balance a high salary against the cost of living. A $90,000 salary in San Jose, CA, may not go as far as a $75,000 salary in a more affordable city in the Midwest with a strong manufacturing base.

###

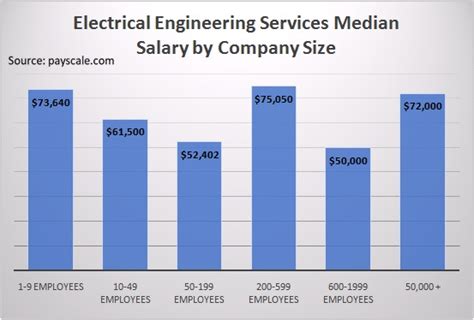

Industry and Company Type

The industry you work in is a major salary driver. Technicians with the same skills can earn vastly different amounts depending on the profitability and technological demands of their sector.

Top-Paying Industries (according to BLS data):

- Scientific Research and Development Services: This industry pays a mean wage of $84,000. These roles often involve working on cutting-edge prototypes and experimental equipment in labs.

- Semiconductor and Other Electronic Component Manufacturing: With a mean wage around $75,560, this high-tech sector requires extreme precision and work in specialized cleanroom environments.

- Aerospace Product and Parts Manufacturing: Mean wage is around $75,250. Working on systems for aircraft and spacecraft demands rigorous adherence to safety and quality standards.

- Federal Government: The federal government, particularly the Department of Defense, is a major employer and offers competitive salaries, excellent benefits, and job security, with mean wages often exceeding $80,000.

Company Type & Size:

- Large Corporations (e.g., Intel, Boeing, Tesla, Procter & Gamble): These companies typically offer higher base salaries, structured career paths, and comprehensive benefits packages. They have the resources to invest in the latest technology and training.

- Startups: A startup in robotics or automation might offer a lower base salary but could include stock options as part of the compensation package, which could become very valuable if the company succeeds. The work is often fast-paced with broader responsibilities.

- Government Agencies (e.g., National Labs, DoD): These roles are known for their stability, excellent benefits, and strong retirement plans. While the base salary might not always be the absolute highest, the total compensation and work-life balance are often superior.

- Original Equipment Manufacturers (OEMs) vs. End-Users: Working for an OEM (the company that builds the machines) as a Field Service Technician often involves travel and pays a premium. Working for an end-user (the factory that uses the machines) offers more stability and less travel.

###

Area of Specialization

Developing expertise in a high-demand niche is one of the most effective ways to command a premium salary.

- Robotics and Automation: Technicians who specialize in programming, integrating, and maintaining industrial robots (e.g., FANUC, KUKA, ABB) are in constant demand in the world of smart manufacturing (Industry 4.0).

- Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs): Expertise in programming and troubleshooting PLCs from leading brands like Allen-Bradley and Siemens is a foundational, high-value skill. Almost every automated system relies on them.

- Semiconductor Manufacturing: This highly specialized field requires technicians who can operate and maintain the incredibly complex equipment used in chip fabrication, such as photolithography, etching, and deposition tools.

- Medical Device Technology: Maintaining and repairing sophisticated medical equipment like MRI machines, CT scanners, and surgical robots requires specialized training and adherence to strict FDA regulations, commanding a higher salary.

- Renewable Energy: Technicians who specialize in the electromechanical systems of wind turbines or solar power facilities are part of a major growth industry.

###

In-Demand Skills

Beyond your formal title, the specific skills you list on your resume will determine your marketability and earning power.

High-Value Technical Skills:

- PLC Programming & Troubleshooting: (Ladder Logic, Structured Text)

- Robotics: (FANUC, KUKA, Universal Robots)

- CAD/CAM Software: (AutoCAD, SolidWorks)

- Pneumatics and Hydraulics: (Understanding and repairing fluid power systems)

- AC/DC Motors and Drives: (VFDs, Servo motors)

- Sensor and Actuator Integration: (Vision systems, proximity sensors)

- Networking and Industrial Communication Protocols: (Ethernet/IP, Profinet)

- Data Analysis and Diagnostics: (Using software to analyze machine performance)

Essential Soft Skills:

- Critical Thinking and Problem-Solving: The core of the job.

- Attention to Detail: Precision is non-negotiable.

- Communication: Clearly explaining technical issues to non-technical staff and documenting your work are vital.

- Teamwork and Collaboration: Working effectively with engineers, operators, and other technicians.

- Adaptability: Technology is always changing, and a willingness to learn is crucial.

By strategically developing these skills, targeting high-paying locations and industries, and pursuing continuous education, you can actively steer your career toward the highest possible salary.

Job Outlook and Career Growth

Choosing a career isn't just about the salary today; it's about the security and opportunity of tomorrow. For electromechanical and mechatronics technicians, the future is bright and interwoven with the most significant technological trends shaping our world.

### Job Outlook for the Next Decade

The U.S. Bureau of Labor Statistics (BLS), in its 2022-2032 projections, provides a solid outlook for this profession.

- Projected Growth: The BLS projects employment for "Electro-Mechanical and Mechatronics Technologists and Technicians" to grow by 2 percent from 2022 to 2032.

- Job Openings: While 2% is categorized as "slower than the average for all occupations," it's essential to look deeper. The BLS anticipates about 1,200 job openings each year, on average, over the decade.

Why is this a positive outlook despite the modest growth percentage? Many of these openings will arise from the need to replace workers who transfer to different occupations or exit the labor force, such as through retirement. This creates a consistent demand for new, well-trained technicians.

The relatively small size of this specialized occupation means that even modest growth translates into a stable number of opportunities. More importantly, the skills of these technicians are becoming more critical, not less. The "slower" growth projection doesn't fully capture the shift in demand *within* manufacturing and other industries. As simple manual jobs are automated, the need for skilled technicians to install, maintain, and repair those automated systems increases dramatically. In essence, the nature of the workforce is changing, and electromechanical technicians are on the winning side of that change.

### Emerging Trends and Future Opportunities

The true story of this career's future lies in the powerful trends driving industrial innovation. Technicians are at the epicenter of this transformation.

- Industry 4.0 and Smart Factories: This is the fourth industrial revolution, characterized by interconnected, automated, and intelligent manufacturing. Factories are being filled