Introduction

From the towering skyscrapers that define our city skylines to the intricate pipelines that fuel our world, the hands of a skilled welder are the invisible force holding modern civilization together. If you're drawn to a career that offers tangible results, a sense of accomplishment, and the ability to build, create, and repair the very fabric of our infrastructure, then welding might be the perfect path for you. But beyond the satisfaction of a perfect bead lies a critical question for any aspiring professional: What can you expect to earn?

The financial potential of a welding career is often underestimated. While the national average provides a solid baseline, the true earning power of a welder is a dynamic figure shaped by skill, specialization, location, and ambition. The average salary of a welder in the United States hovers around $50,000 annually, but this is merely a starting point. Entry-level positions may begin in the $35,000 range, while highly specialized, experienced master welders working in critical industries can command salaries well into the six-figure territory, sometimes exceeding $150,000 or more with overtime and specialized work.

As a career analyst, I once had the opportunity to interview a team of welders working on a major natural gas pipeline project in a remote location. The lead welder, a man with over 20 years of experience and a slew of advanced certifications, spoke not just of the excellent pay, but of the immense responsibility. "One bad weld out here," he said, gesturing to the vast, empty landscape, "and the consequences are enormous. We're not just joining pipes; we're ensuring the safe flow of energy to millions. That responsibility is what you're paid for." His words underscore a fundamental truth: in this trade, expertise is not just valued; it is essential, and it is rewarded.

This comprehensive guide will illuminate every facet of a welder's salary and career trajectory. We will dissect the national averages, explore the critical factors that can dramatically increase your earning potential, and provide a clear, actionable roadmap for anyone looking to enter and excel in this vital and rewarding profession.

### Table of Contents

- [What Does a Welder Do?](#what-does-a-welder-do)

- [Average Welder Salary: A Deep Dive](#average-welder-salary)

- [Key Factors That Influence a Welder's Salary](#key-factors)

- [Job Outlook and Career Growth for Welders](#job-outlook)

- [How to Become a Welder: A Step-by-Step Guide](#how-to-become-a-welder)

- [Conclusion: Is a Welding Career Right for You?](#conclusion)

---

What Does a Welder Do? The Art and Science of Fusing Metal

At its core, welding is the process of using extreme heat and pressure to join metal parts permanently. A welder, therefore, is a skilled tradesperson who specializes in this process, transforming separate pieces of metal into a single, durable structure. This work is both a science, requiring a deep understanding of metallurgy and physics, and an art, demanding manual dexterity, precision, and a steady hand.

The scope of a welder's work is incredibly broad, touching nearly every major industry. They are the builders of ships, the fabricators of airplanes, the assemblers of automobiles, and the constructors of bridges and buildings. They work in manufacturing plants, on construction sites, in naval shipyards, and even in the extreme environments of underwater oil rigs or high-altitude aerospace facilities.

Core Responsibilities and Daily Tasks:

A welder's duties extend far beyond simply operating a torch. A typical project involves a multi-step process that requires a diverse skill set:

- Interpreting Blueprints and Schematics: Before any heat is applied, a welder must be able to read and understand technical drawings, blueprints, and welding procedure specifications (WPS). This tells them the type of weld required, the materials to be used, the dimensions of the project, and the specific process to follow.

- Preparing Materials: Metal surfaces must be meticulously cleaned and prepared before welding. This can involve grinding, cutting, chipping, or beveling the edges of the pieces to ensure a strong, clean joint free of contaminants.

- Setting Up and Maintaining Equipment: Welders are responsible for selecting and setting up the correct welding equipment for the job. This includes choosing the right power source, electrodes, filler wire, and shielding gas, and ensuring all equipment is in safe, working order.

- Executing the Weld: This is the primary function. The welder uses one of several processes—such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW/MIG), or Gas Tungsten Arc Welding (GTAW/TIG)—to melt and fuse the metal components. This requires immense focus and control to maintain the correct arc length, travel speed, and angle.

- Quality Control and Inspection: After the weld is complete, the work isn't done. The welder must inspect the finished joint for defects like cracks, porosity, or lack of fusion. This can involve visual inspection, as well as more advanced non-destructive testing (NDT) methods. They may need to chip or grind away excess slag or spatter to finish the piece.

- Adhering to Safety Protocols: Welding is an inherently hazardous job, involving high temperatures, intense ultraviolet light, fumes, and electrical shocks. A critical part of the role is rigorously following safety procedures, including wearing appropriate Personal Protective Equipment (PPE) like welding helmets, flame-resistant clothing, and respirators.

> A Day in the Life of a Fabrication Shop Welder

>

> 7:00 AM: Alex arrives at the fabrication shop, clocks in, and heads to the morning safety briefing. The supervisor reviews the day's projects, highlighting specific safety concerns for a large-scale structural steel assembly.

>

> 7:30 AM: Alex's first job is to fabricate a series of support brackets for an industrial catwalk. He retrieves the blueprints, studies the required weld symbols, and gathers the pre-cut steel plates.

>

> 8:00 AM: He spends the next hour preparing the metal. Using an angle grinder, he bevels the edges of the plates to the precise angle specified in the plans, ensuring proper penetration for the weld.

>

> 9:00 AM: Alex sets up his MIG welding machine, calibrating the voltage and wire feed speed for the thickness of the steel. He dons his welding helmet and leathers and begins tack welding the pieces into place, carefully measuring to ensure everything is square and to spec.

>

> 10:00 AM - 12:00 PM: With the bracket tacked together, Alex performs the full structural welds, laying down clean, consistent beads. The air fills with the hum of the machine and the bright flash of the arc, which is safely hidden behind his auto-darkening helmet.

>

> 1:00 PM: After lunch, Alex moves to a different project: TIG welding on a set of stainless-steel food-grade counters. This requires much more finesse and a different machine setup. The work is slower, more precise, and demands intense concentration.

>

> 3:30 PM: The welding is complete. Alex carefully inspects his welds, cleans them with a wire brush, and checks them against the blueprint one last time. He then moves the finished pieces to the quality control area for final inspection.

>

> 4:30 PM: Alex spends the last part of his day cleaning his work area, performing basic maintenance on his welding machine, and preparing for the next day's projects before clocking out.

---

Average Welder Salary: A Deep Dive into Compensation

Understanding the financial landscape of a welding career begins with national averages but truly comes into focus when examining the full spectrum of compensation, from entry-level wages to the earnings of seasoned experts.

### National Averages and Salary Ranges

The most reliable source for occupational data, the U.S. Bureau of Labor Statistics (BLS), provides a comprehensive look at welder pay. According to the BLS's Occupational Outlook Handbook, the median annual wage for welders, cutters, solderers, and brazers was $47,540 in May 2023. This means that half of all welders earned more than this amount, and half earned less.

However, the median only tells part of the story. The full range of pay reveals the significant growth potential within the field:

- Lowest 10%: Earned less than $37,010

- Highest 10%: Earned more than $72,970

It's crucial to note that the BLS data often represents a baseline and may not fully capture the high earnings potential from extensive overtime, per diem allowances for travel, and hazardous duty pay, which are common in many high-demand welding jobs.

Reputable salary aggregators, which collect real-time, user-submitted data, often paint a slightly different and more granular picture.

- Salary.com reports that as of late 2023, the median salary for a mid-level welder (Welder II) is closer to $54,309, with a typical range falling between $48,393 and $61,777.

- Payscale.com shows a similar average base salary of around $23.16 per hour, which translates to approximately $48,170 annually for a standard 40-hour week. Their data also highlights that overtime can significantly boost total annual pay, often adding $5,000 to $15,000 or more per year.

- Glassdoor places the total pay average for a welder in the U.S. at $60,248 per year, which includes an estimated average of $7,639 in additional pay like cash bonuses, profit sharing, and commissions.

### Salary by Experience Level

A welder's income grows in direct correlation with their experience and proven skill. The career path typically progresses from an apprentice or entry-level position to a journeyman and, eventually, to a master or senior welder.

| Experience Level | Typical Years of Experience | Estimated Annual Salary Range (Base) | Key Characteristics & Responsibilities |

| :--- | :--- | :--- | :--- |

| Entry-Level / Apprentice Welder | 0-2 Years | $35,000 - $45,000 | Learning basic welding techniques (e.g., SMAW, GMAW). Works under direct supervision. Focuses on material preparation, workshop cleanup, and simple fabrication tasks. |

| Mid-Career / Journeyman Welder | 3-9 Years | $45,000 - $65,000 | Proficient in multiple welding processes. Can read and interpret complex blueprints independently. Holds one or more certifications. Capable of performing quality control and troubleshooting minor issues. |

| Senior / Master Welder | 10+ Years | $65,000 - $90,000+ | Expert in advanced and specialized welding processes (e.g., TIG, pipe welding). Often holds multiple advanced certifications (e.g., AWS CWI). May lead teams, train junior welders, or work on the most critical, high-stakes projects. |

*(Salary ranges are estimates synthesized from BLS, Salary.com, and Payscale data and do not include overtime or other bonuses, which can significantly increase these figures.)*

### Beyond the Base Salary: Understanding Total Compensation

A welder's paycheck is often more than just their hourly wage or annual salary. Total compensation is a package that can include several lucrative components, especially for those willing to travel or work in demanding sectors.

- Overtime Pay: This is one of the most significant factors in a welder's total earnings. Many industries, such as manufacturing, construction, and energy, operate on tight deadlines, requiring welders to work more than 40 hours a week. This overtime is typically paid at 1.5 times the base hourly rate ("time-and-a-half") and can dramatically increase annual income.

- Per Diem Allowances: Traveling welders, particularly those working on cross-country pipelines, industrial shutdowns, or remote construction projects, receive a "per diem." This is a daily stipend designed to cover living expenses like lodging, food, and incidentals while away from home. This allowance is often tax-free and can add tens of thousands of dollars to a welder's annual take-home pay.

- Bonuses and Profit Sharing: In some manufacturing and corporate environments, welders may be eligible for performance bonuses, safety bonuses (for maintaining an accident-free record), or profit-sharing plans. These are designed to incentivize efficiency, quality, and a commitment to the company's success.

- Hazardous Duty Pay: Welders working in exceptionally dangerous environments—such as at extreme heights, in confined spaces, or underwater—receive a significant pay differential to compensate for the increased risk. Underwater welders, for example, are among the highest-paid professionals in the trade precisely because of the hazards involved.

- Benefits Package: While not direct cash, a strong benefits package is a vital part of compensation. This typically includes health, dental, and vision insurance; a retirement plan like a 401(k) with a company match; paid time off; and sometimes, tuition reimbursement for further training and certifications. Union welders often have some of the most comprehensive and robust benefits packages in the industry.

---

Key Factors That Influence a Welder's Salary

The difference between earning a modest wage and a six-figure income as a welder lies in a combination of strategic choices and cultivated expertise. Several key factors directly influence salary potential, and understanding them is crucial for career planning.

###

1. Level of Education and Certification

While a four-year university degree is not required to become a welder, the level and quality of your technical training have a direct impact on your starting salary and long-term career trajectory.

- High School Diploma / GED: This is the minimum requirement to enter the field, but it will typically lead to the lowest-paying, most basic entry-level positions.

- Vocational School Certificate / Diploma: This is the most common and effective entry point. Programs at technical colleges and vocational schools typically last from 6 months to 2 years and provide foundational knowledge in safety, various welding processes, and blueprint reading. Graduates are far more attractive to employers and can command higher starting wages than those with no formal training.

- Associate's Degree in Welding Technology: A two-year degree goes beyond the basics, covering more advanced topics like metallurgy, destructive and non-destructive testing, robotics, and welding inspection. Graduates are well-positioned for higher-level technician roles or to move more quickly into leadership or inspection positions, which come with higher salaries.

The Power of Certification:

Professional certifications are arguably the single most important educational factor for increasing a welder's pay. Certifications are credentials that prove a welder has the skill to perform a specific type of weld according to a particular code or standard. The American Welding Society (AWS) is the primary certifying body in the U.S.

- Certified Welder (CW): This is a widely recognized entry-level certification that demonstrates a welder can perform a weld according to a specific AWS standard. Having this can immediately set a candidate apart and boost starting pay.

- Specialized Certifications: Certifications in specific processes (e.g., TIG), positions (e.g., 6G pipe welding), and materials (e.g., stainless steel, aluminum) are highly valued and lead to higher pay. For example, a welder certified in 6G pipe welding, which involves welding a pipe in a fixed, angled position, has proven they can handle complex work and is in high demand in the lucrative pipeline and power plant sectors.

- Certified Welding Inspector (CWI): This is a significant career advancement. A CWI is responsible for inspecting the work of other welders to ensure it meets code and quality standards. It's a role with immense responsibility that requires years of experience and passing a rigorous exam. CWIs regularly earn salaries in the $70,000 to $100,000+ range.

###

2. Years of Experience and Skill Progression

As detailed in the salary table, experience is a primary driver of income. However, it's not just the number of years on the job but the *quality* of that experience that matters.

- Apprentice (0-2 years): In this phase, the focus is on learning. Pay is lower, but the value is in the on-the-job training received under the guidance of a journeyman.

- Journeyman (3-9 years): A journeyman welder is a fully qualified professional who works independently. Their salary increases as they master more processes, work with different materials, and prove their reliability and quality. A journeyman with 5 years of experience in high-pressure vessel welding will earn significantly more than one with the same tenure doing basic fabrication.

- Master Welder / Lead (10+ years): A master welder possesses an elite level of skill. They are the go-to experts for the most challenging projects. They often take on leadership roles, mentoring junior welders, planning complex jobs, and collaborating with engineers. Their deep expertise, problem-solving ability, and leadership qualities command the highest salaries in the hands-on side of the trade.

###

3. Geographic Location

Where you work as a welder has a massive impact on your paycheck. This is driven by the concentration of specific industries, local demand, and the regional cost of living.

Top-Paying States for Welders:

According to the BLS, some of the states with the highest annual mean wages for welders are often tied to the energy, defense, and shipping industries:

1. Alaska: ($76,010) - Driven by the oil and gas industry and remote infrastructure projects.

2. Wyoming: ($69,150) - Strong presence of mining, oil, and gas extraction.

3. District of Columbia: ($68,360) - Government and infrastructure projects.

4. North Dakota: ($65,560) - Major hub for oil and gas (Bakken formation).

5. Hawaii: ($63,780) - Military shipyards (Pearl Harbor) and high cost of living.

Conversely, states with lower concentrations of heavy industry and a lower cost of living tend to have lower average welder salaries.

Metropolitan vs. Rural Areas:

Salaries are often higher in major metropolitan areas with significant industrial bases (e.g., Houston, TX; Baton Rouge, LA) to offset a higher cost of living. However, some of the highest-paying jobs are in *remote* rural areas where major energy or mining projects are underway. These jobs offer high base pay plus significant per diem and overtime to attract skilled labor to inconvenient locations.

###

4. Industry and Company Type & Size

The industry you work in is a powerful determinant of your salary. A welder's skills are transferable, but their value fluctuates depending on the sector's profitability and demand for precision.

- Oil & Gas (Energy): This is consistently one of the highest-paying sectors. Pipeline welders, rig welders, and those in refineries perform critical, high-pressure work, often in harsh conditions, and are compensated accordingly. Salaries can easily exceed $100,000 with overtime.

- Aerospace & Defense: This sector demands the utmost precision and quality. Welders working on aircraft, spacecraft, and military equipment must often be certified to work with exotic alloys like titanium and Inconel. TIG welding is a premium skill here, and salaries are very high to reflect the zero-tolerance for error.

- Commercial Construction & Infrastructure: Welders are essential for building bridges, skyscrapers, and other large structures. Pay is strong, often governed by union-negotiated rates, which provide excellent wages and benefits.

- Shipbuilding: Both commercial and military shipbuilding requires thousands of welders. This is a stable, high-demand field, particularly in coastal states with major shipyards.

- Manufacturing: This is the largest employer of welders. Pay can vary widely. A welder in a small, local fabrication shop may earn a modest wage, while a welder/robotic technician in a state-of-the-art automotive plant can earn a very competitive salary.

- Government/Military: Welders employed directly by the military or government agencies (e.g., as a civilian in a Navy shipyard) have job security and excellent benefits, though their base pay might be slightly lower than in the top private sectors.

Company size also plays a role. Large multinational corporations (e.g., Boeing, ExxonMobil) or major unions (e.g., a Pipefitters local) often have structured pay scales and benefits packages that lead to higher overall compensation than small, independent fabrication shops.

###

5. Area of Specialization

General fabrication welders are always needed, but specializing in a difficult, high-demand niche is the fastest way to maximize your income.

- Underwater Welding: This is the most famous high-paying specialty. Working in a hyperbaric environment to repair ships, oil rigs, and underwater pipelines is extremely dangerous and requires a unique combination of commercial diving and welding skills. Experienced saturation divers/welders can earn $100,000 to over $200,000 per year.

- Pipe Welding (especially "Rig" or Pipeline Welding): Pipe welders who can pass stringent 6G certification tests are elite professionals. They work on pipelines, in power plants, and in refineries where weld failure is not an option. Traveling pipeline welders who own their own "rig" (a truck equipped with a welding machine and tools) can earn exceptionally high incomes.

- TIG (Tungsten Inert Gas) Welding: TIG welding is a precise, clean process used on thin-gauge metals, stainless steel, aluminum, and exotic alloys. It is essential in the aerospace, nuclear, medical, and food-grade industries. TIG welders consistently command a higher hourly wage than general MIG welders.

- Robotic / Automated Welding Technician: As automation increases, there is a growing demand for technicians who can program, operate, and maintain robotic welding cells. This role combines traditional welding knowledge with robotics and programming skills, placing it at the high end of the manufacturing pay scale.

- Welding Inspector (CWI): As mentioned earlier, moving from "on the tool" to an inspection role is a lucrative career path. CWIs are crucial for quality assurance in every major industry.

###

6. In-Demand Technical and Soft Skills

Beyond formal certifications, a portfolio of specific, demonstrable skills can significantly boost your value.

- Blueprint Reading Proficiency: The ability to flawlessly read and interpret complex schematics, including weld symbols, is non-negotiable for high-paying jobs.

- Multi-Process Proficiency: Being an expert in a single process is good, but being highly skilled in multiple processes (SMAW, GMAW, GTAW, FCAW) makes you far more versatile and valuable to an employer.

- Knowledge of Metallurgy: Understanding how different metals react to heat, the properties of various alloys, and how to prevent issues like distortion and cracking is a sign of an advanced practitioner.

- Rigging and Fitting: Welders who can also accurately measure, cut, and fit their own materials (pipefitters/welders, for example) are more efficient and can command higher pay.

- Safety Record: A documented, long-term commitment to safety protocols (e.g., OSHA certifications) is highly attractive to employers, especially in high-risk industries.

---

Job Outlook and Career Growth for Welders

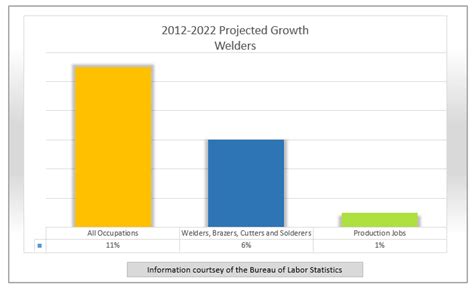

The career outlook for welders is a nuanced topic that requires looking beyond the headline numbers. While the U.S. Bureau of Labor Statistics projects slower-than-average growth for the occupation, this statistic can be misleading and fails to capture the full picture of opportunity within the trade.

### The Numbers: Growth and a Widening Skills Gap

The BLS projects that employment for welders, cutters, solderers, and brazers will grow by 2 percent from 2022 to 2032. This is slower than the average for all occupations. However, the report also projects about 40,900 openings for welders each year, on average, over the decade.

Where is the disconnect? Most of these openings are not expected to come from the creation of new positions but from the need to replace workers who retire or transfer to different occupations. The American Welding Society has highlighted a critical challenge for years: a massive, impending "skills gap." A large portion of the current highly skilled welding workforce is at or nearing retirement age, and there are not enough new, skilled welders entering the field to replace them.

This creates a paradox: while the overall number of jobs may not be booming, the demand for skilled, certified, and reliable welders is intense and growing. Employers consistently report difficulty in finding qualified candidates, which drives up wages and creates significant opportunities for those who invest in their training and skills.

### Emerging Trends Shaping the Future of Welding

The world of welding is not static. Several key trends are transforming the profession, creating both challenges and exciting new avenues for career growth.

1. **Automation and Robotics